مقالات تکنولوژی و تجهیزات ابکاری

English-ملاحظات درانتخاب تجهیزات آبکاری تکنولوژیکی

- مقالات علمی

- بازدید: 104523

finishing equipment & plant engineering

CONSIDERATIONS IN THE FINISHING

EQUIPMENT SELECTION PROCESS

CJI PROCESS SYSTEMS, SANTA FE SPRINGS, CALIF.

When budgeting for new finishing equipment or upgrading an existing line,

it is important to note that each requirement is unique and must be carefullyconsidered before estimating a price. Otherwise, when the real purchase ordermaterializes for the quoted system, all of the pre-engineering data must be available,as well as current costs, in order to build a particular line. This article willdescribe several key considerations in the selection process of a custom manualor automated plating, anodizing, or chemical process system.Beyond the obvious—selecting floor coating, secondary containment trays, orberming, power, air, and exhaust requirements—the equipment selection processmight proceed as follows:

• The equipment estimator must first collect all the data.

• Then, a determination of how many parts are to be finished peryear, month, week, day, must be broken down into hours per day,in order to size the process line.

• Pretreatment requirements, such as burnishing, tumbling, deburring,buffing, polishing, or degreasing, and selection of any specializedequipment, must be considered.

• Selection of the process, which will depend on whether the partsneed to be barreled or racked, is yet another factor.

• Determine a plating or anodizing process cycle for the particularbase material, as well as the configuration of the parts.

• Determine if the plating thickness requires electroplating,immersion, or autocatalytic (electroless) processing or Type I, II, or IIIanodizing, etc.

• Carefully calculate the surface area of a single part to determinehow many parts may be loaded per barrel, rack, or fixture.

• If the parts are to be barrel plated, then determine if the parts willnest, or stick together; and, if so, what type of barrels will be used.

• If the parts are to be racked, then each part needs to have a specialrack or fixture designed to accommodate that special part. If morethan one rack per flight bar is required, determine just howmany racks per load will achieve the best results.

• Masking considerations: Many parts will require masking withspecial tapes or waxes, as well as holes plugged with custom plugs.

• Reels of connector parts might require selective plating only insome areas, especially where precious metals are plated.Customized selective strip plating lines will be required for eachspecial application.

Once the production quantities are determined, then the plating facility mustbe sized accordingly. The plating tanks must be laid out, and the footprint of alllines and systems measured, with optional floor coating, double containmentof the tanks, with catwalk and grating provided. If a manual line is sufficientfor the desired production volume, with one or more operators, then it mustbe determined if anoverhead hoist will be needed—and if so, will it be a manualchain hoist, powered trolley with push button, or joy stick variable-speed motorized hoist.

???

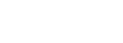

Automatic solar panel plating line.

(All images courtesy of CJI Process Systems)

Phosphate line.

If an automatic hoist line is needed,then you’ll need to determineprecisely how many hoists will berequired. Depending on the configurationof the line, there might beparallel lines, side by side, with load,unload at the same end, or load onone end, unload on the other end,and with either wet or dry shuttletransporting the barrels or racksfrom one side of the line to the other,or a U-shaped return line, and dryer.The PC software must be programmablein order to allow controlof all the process parameters, suchas solution operating temperatures;low-level shut off, alarms, auto-fillof tanks; variable or constant currentand voltage requirement of therectifiers; cathodic or anodic; automaticramp up of voltage for anodizing;historical process data recordedfor future records; hoist location,position, and speeds; pumps andfiltration operation; air blower pressure;and amp min/hr. Other parametersto consider are chemical dosing,and if any brightener feeders orchemical feeders are supplied withmetering pumps, etc.In order to design the plating line(s) correctly, key items must consideredfor every single tank in the line. The designer must go through each station ortank, one at a time, to decide which controls or accessories need to be installedon each tank. A manual line would need the same items as an automated line,except the automated line would have either single or multiple programmablehoists, which might be either a monorail type, sidearm, semi-bridge, bridge, or a“rail rider.” The hoist positioning might be laser-controlled encoder or manual,with random loading scheduling—or it could be time-way based. The line mightbe totally enclosed because of either clean room or other environmental circumstances,with the operator working inside the enclosure.All of the tanks must be sized to accommodate the barrels, or racks, with sufficientclearance for the heaters, sensors, coils, pumps, filters, spargers, level controls, anode baskets, etc. The tank materialmust be chemically compatible—withthe decision to either line the tank,or offer it without linings or innercoatings—for each solution, as wellas each individual component. Eachtank must be outfitted with a varietyof components, based on just whatthe tank is supposed to accomplish.The soak cleaner would needeither electric heaters or heatingcoils, temperature controllers, sensors,hi/lo level sensors, individualsolenoids for city water or deionizedwater feed, agitation sparger(with agitation either provided bylow-pressure, oil-free filtered air),or eductor/pump agitation. Othernecessities: oil skimmer, oil coalescer,pump and filter, and low-levelshut off of the heater.The rinse tanks might requireauto-fill city or deionized water solenoids,air sparger manifolds, drainvalves, overflow weirs, conductivitycontrollers, and possibly pump andfilter, depending on particulate drug into them. Electro-cleaner tanks wouldalso need a rectifier, anode/cathode bars, pump and filter, oil skimmer, heateror steam coil, solenoids for city and deionized water feed, etc.The process tanks would require similar components as the electro-cleaner, withan addition of rectifiers and other items, depending on the process. The rectifiersmight be chosen to accommodate a variety of controls, such as constant currentand/or constant voltage (pulsed, periodic reversed, or reverse pulsed; air, water, orconvection cooled), and might include analog or digital amp/volt meters mountedremotely. The designer must decide just what type of heaters, agitation, cooling,filtration, circulation, rectification, and materials of construction, as well as whatneeds to be exhausted and which tanks need exhaust plenums. CFM requirementsalso need to be calculated for the entire line in order to size the air scrubber.If the plating tank happens to be an electroless nickel process, then the decision

must be made as to how to heat the tank. For example, would it be morepractical to use heaters, steam, or hot water coils? Or does it make more sense to make the tank a double-boiler tank heated with coils in the lining of the tank?

???

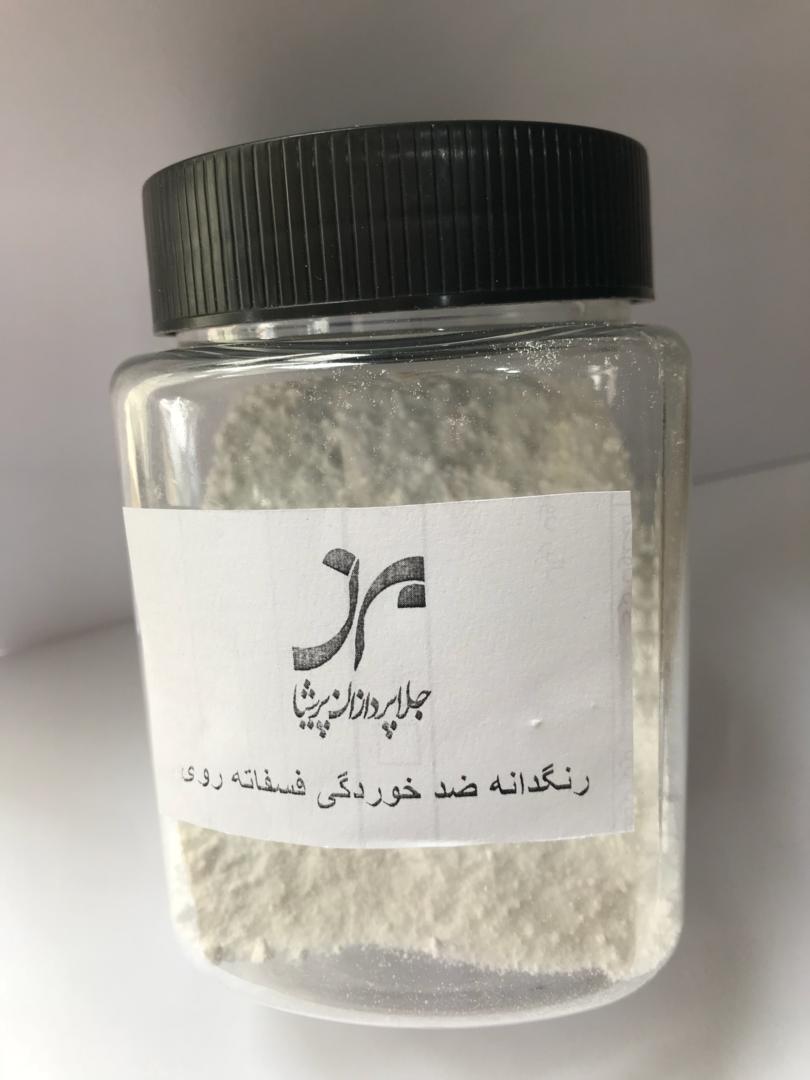

Rear view of large plating line.

Automatic electroless nickel plating line.

CONSIDERATIONS WHEN DESIGNING A TANK

There are many considerations when building the tanks, including size, quantity,and spacing of the girths around each tanks, as well as factoring in the weightcapacity of each solution. All of this depends on specific gravity, operating temperature,and geographical location. On the West Coast, for example, you mightrequire seismic calculations on the larger tanks.The plating lines might be either individual tanks sitting on a frame or mod- ules. Either way, the lines should be plumbed with valves, solenoids, city anddeionized water feeds, with separate drains to cyanide, acid/alkaline, and chromelines to the wastewater treatment system. Note: every plating facility will needsome type of treatment system, unless it’s all hauled away and treated off site.The plating line should offer single-point connections after arriving for hook upof the utilities, air, water, or steam, and electricity. Most plating lines are wired“three-phase” wherever possible for energy efficiency savings.Some plating lines are required to provide VFC (variable frequency controls)that vary the speed of the electric motors on the pumps, etc., depending on loadrequirements.The wastewater treatment system must have many components to accommodatethe plating line, and the plating line designer is usually asked to also quotethe wastewater system supporting the plating or anodizing line. Aside fromconsiderations regarding the wastewater treatment methodology of each platingline, the designer must determine just which type of system will be the mostefficient system for that particular line while satisfying the local permitting laws.

CONCLUSIONS

The aforementioned factors should offer readers just a few examples of themagnitude of calculations, researching, sizing, etc., that might be required whenestimating a new system. If the process line is designed properly to begin with, then the chemistry will have a much better opportunity of being successful.

مقالات دیگر این نویسنده

- استاندارد ISO 5000 داغی مداوم - شیب آلومینیوم / سیلیکون سرد پوشش داده شده - کاهش کیفیت پوشش ورق فولاد کربن از نظر تجاری

- مواد فعال سطحی دو خصلتی یا آمفوتری

- استاندارد ISO 2178 پوشش های غیر مغناطیسی بر روی بسترهای مغناطیسی - اندازه گیری ضخامت پوشش - روش مغناطیسی

- کاریکاتور جالب محیط زیست

- -سئوال و جواب - آبکاری روی و آلیاژ روی English