مقالات تکنولوژی و تجهیزات ابکاری

english-افزایش کارایی در تجهیزات آبکاری برای ارتقای رقابت پذیری

- مقالات علمی

- بازدید: 124096

finishing equipment & plant engineering

FINISHING SYSTEM EFFICIENCY

UPGRADES FOR A CAPITALCONSTRAINED

MARKET

BY TIMOTHY KURCZ, DIRECTOR OF SALES, JESSUP ENGINEERING,

ROCHESTER HILLS, MICH.

During this furtive economic recovery, captive and independent finishers facethe need to increase capacity, improve quality, and reduce resource consumptionas rising production volumes stretch a downsized industrial base. This challengeis the result of wholesale market consolidation and continued global competitivepressure. Unfortunately, recently imposed government banking controls limitcapital availability and the option to purchase new machinery no matter howstrong the business case.With many new installations out of the picture for the short term, the toooftenemployed lowest cost solution is simply to increase demand on alreadystressed human/machine resources. This is risky given the operator-sensitivenature of the finishing business and finicky, well-worn machines. A better choiceis targeted investment of carefully engineered upgrades designed to enhanceexisting plating, anodizing, coating, and other types of finishing systems.Jessup Engineering,1 known as a leading manufacturer of programmablehoists and turnkey finishing systems, responded to customer demand for costeffective,incremental machine improvements. Every customer installationrequires careful analysis to fully understand, engineer, and prioritize improvementopportunity. Partnership work teams establish targets, and the customerselects the most cost-effective solution for each machine. Over the past year, thefollowing upgrades achieved specific productivity goals for Jessup customers’existing plant and equipment.

1) An intuitive touch screen industrial personal computer/humanmachine interface (PC/HMI) is the heart of every Jessup controlsupgrade (Figure 1). Available with single-touch toggled bilingual languageformat, it displays system overviews, recipe options, hoist programming, load/unload monitoring, process functions, load tracking,fault diagnostics, and pre-programmed maintenance schedules. Forconvenience, it also includes imbedded drawings, schematics, operationsmanuals, and spare parts lists. Control features include monitoringand control of hoist equipment, process tanks, and accessory equipment.Quick scan input devices may include bar code or radio frequencyidentification (RFID) technology. PC-controlled programmable logiccontroller (PC/PLC) systems provide load-by-load output data in asimple comma separated variable file (CSV) format for interface withcustomer quality and business management systems through Ethernetcommunications. Performance monitoring includes shift reports fortotal time and cycles, automatic vs. manual operation, load/unloaddelay, and fault data. To speed correction of unexpected stoppages, the control system provides automatic system diagnostics. Detailed screen

؟؟؟

Figure 1. Jessup PC/HMI operator screen image

???

Figure 2. Jessup rectifier control screen.

???

Figure 3. Jessup chemical feed control screen.

???

Figure 4. Jessup rinse water management screen.

display fault location and actions needed to quickly restore production.Internet-based remote monitoring expedites troubleshooting and repairs.Specific screen pages may include:

a) System overview, including hoists, tanks, carriers, etc.

b) Alarm history provides a view of recent alarm information.

c) Hoist programming requires no programmer or special devices.

d) Machine diagnostics provides detailed faultinformation.

e) Service reminder recommends maintenanceprocedures.

f) System security requires login and password for access.

g) Shift report provides machine performance data.

؟؟؟

Figure 8. Jessup cylindrical vs. hex barrel comparison.

k) Bar code or keypad interface for recipe input.

l) Load-by-load data capture, storage, and export.Except in cases where simple fixed process cycles run, or where machine

management and data recording is unnecessary, PC/HMI operation of finishingsystems is standard for all new machines. Retrofits are easily accomplished.They often include machine position sensors, rinse water control systems, andprogrammable chemical feed pumps. Machine monitoring, management, loadby-load data recording and paperless quality management features offer quick

return of customer investment

2) Programmable, recipe-based individual cell rectification enables precise,repeatable plating thickness for every load regardless of part count forrack plating, or weight for barrel plating operations (Figure 2). ThisPC-driven feature derives and calculates surface area data from a customer-supplied lookup table on a discreet part number basis. Operatorentered load data assures precise amp square foot (ASF) delivery for rackplating systems. Barrel weight is verified directly by load cells by eitheraddition or subtraction methods. This assures correct ASF delivery forbarrel plating systems. Installation of individual rectifiers integratedwith a PC/HMI recipe-driven controls make over- and under-plating a

3) Programmable chemistry replenishment reduces operator workload andimproves quality by reducing fluctuations in process baths. This recipedrivenfeature assures precise additions based on PC-tracked productioninformation. The goal is to dampen the bath concentration saw-tootheffect common with manual addition practices. Precision control is availableonly by an integrated PC/HMI. The control screen allows external adjustment of replenishment volumes at any time during machine opera-distant memorytion (Figure 3). Installation of PC/HMI-driven chemistry managementcontrols will improve quality and reduce operator addition errors.

4) Programmable load-by-load rinse water replenishment allows optimizationof water consumption on an individual part number basis.This feature enables experimentation with the minimum rinse watervolume necessary to assure quality processing. The goal is to minimizetotal rinse water usage, thus reducing wastewater treatment volumeand associated chemistry consumption. Precision control is availableonly by an integrated PC/HMI. The control screen allows separatereplenishment volumes for full or empty loads, further minimizingrinse water usage (Figure 4). Installation of PC/HMI recipe-drivenrinse water controls will immediately reduce rinse water consumptioncompared to constant flow rinse water replenishment systems.

5) Variable plate time programming for multi-process machines allowsmultiple immersion times and cycle options while maintaining repeatableprocess parameters. Production rate remains fixed to take bestadvantage of material handling equipment. The Jessup variable platingtime process accepts work with differing plating tank immersiontimes while retaining predictable and repeatable process times in other areas of the machine (Figure 5). Immersion times are a multipleof the machine cycle time. This approach guarantees repeatable plating at a constant production rate. Load/unload operations andexternal logistics remain unaffected. Also available is process cyclere-engineering to speed changeover between processes. This becomesincreasingly important as the industry shifts to smaller lots, whichrequire more frequent break-in sequences. Retrofit hoists, controls,and variable plate time programming eliminate guesswork and operatorsensitivity associated with older simple-cycle multi-process finishingsystems.

6) NADCAP & ISO quality system capable automation is assured withPC/HMI over-the-top and appropriate sensor technology monitors,controls, and records critical quality control information. Data suchas tank temperatures, immersion times, rectification, pH, conductivity,barrel rotation or oscillation speed and/or duration, chemistryadditions, and rinse water usage is collected and stored on a load-byloadbasis. Further, data is exported to the customer data highway forupload into quality management database. This system creates trulypaperless quality control. The Jessup PC/HMI system captures moredata than end-user customers require. The finisher’s quality controldepartment will have access to current and historical trend data neverbefore available.

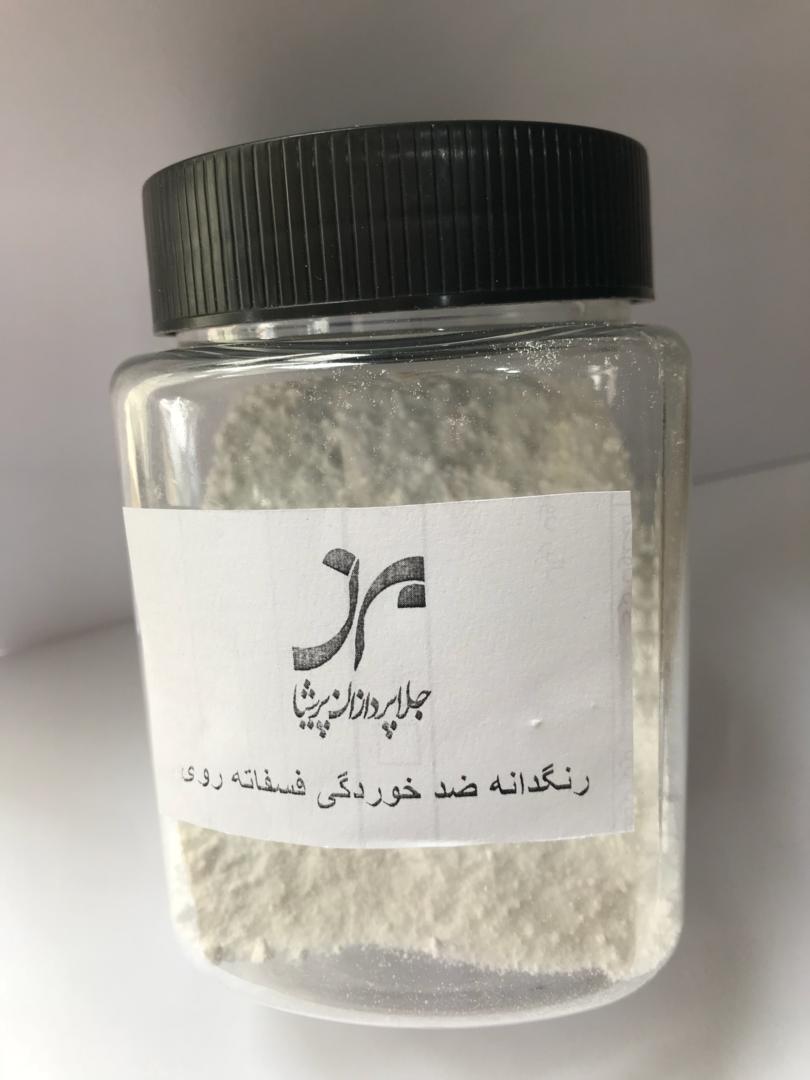

7) Jessup cylindrical barrels can offer 17% increased capacity and 12%better work-to-anode relationship compared to hex barrels for moreproductive plating. More consistent anode-to-work relationshipimproves plating efficiency (Table 1). The drawing and comparisonchart clearly illustrate capacity and work-to-anode differences. Jessupplating barrel design features include: a one-piece cylindrical shell;tongue-and-groove, double-welded construction; integrated, heatfusedtumbling ribs; CNC drilled or slotted perforation patterns forshorter drain dwells; and knob or quick-change inside-out style loadlockercovers (Figures 7 & 8). A machine specific tab-lock design isalso available for Jessup robotic cover handling systems used for fullyautomated bulk load/unload systems.Jessup cylindrical barrels retrofitted to your plating line can deliver17% more production with no other machine changes compared tohex barrels. The example 60-inch-wide barrels fit an identical workspaceanode. Run at 12 loads per hour (LPH), the Jessup barrel delivers

8.16 more cubic feet. At 20 hours per day, this equates to 163.2 morecubic feet. If this machine runs 240 days per year, the difference is anincredible 39,168 cubic feet more production delivered on an annualbasis by installing Jessup barrels!Jessup barrels are also available with center partitions, enabling largemachines to process smaller lot sizes. This feature assures optimummachine utilization and maintains critical workload separation when combined with divided load/unload systems. PC over-the-top controlstrack, record, and export separate data for part numbers run simultaneouslyto a customer data highway for paperless quality controlmanagement and reporting. Partitioned barrels add small lot flexibilityto large capacity machines.

8) The Jessup single-point set-down superstructure design incorporatesfixed drive gear engagement (Figure 9). This eliminates ratchetingassociated with designs using adjustable gear mesh. It also reduceswear and tear on motors, drives, and associated components by eliminatingsuperstructure rock common to multi-point set-down designs.Delicate parts suffer from one-process-fits-all rotation management.

Recipe-driven control of barrel rotation and/or oscillation with a PC/HMI enables gentler treatment of sensitive parts (Figure 10). If newbarrels and superstructures are part of a customer upgrade plan, thesingle-point set-down design and individual barrel control is a welcomeimprovement when integrated along with new drives and saddles.

9) Hoist-mounted barrel drives engage in the up position, allowingbarrel rotation during the process cycle (Figure 11). Programmablespeed and duration dramatically reduce drag-out induced carry overby draining work directly over the process tank. This feature is especiallyimportant for parts known to cup solution. PC/HMI controlledup rotation combined with rinse water management reduces waterconsumption, waste treatment, and chemistry usage. Up-barrel rotationis mandatory for critical resource reduction needed in today’shighly competitive finishing environment.

10) Hoist and motion control upgrades such as high efficiency VFDcontrolled Energy Star-rated Eurodrive motor/drive combinationsfor electrical energy savings. Smooth-operating, corrosion-proof beltlift conversions replace older wound wire cables. This dramaticallyextends hoist lift maintenance intervals. Full-length, non-contactabsolute linear encoders allow faster hoist operation with smoothermotion profiles eliminating rack or barrel shake (Figure 12).Together they improve machine productivity and operator safety.Finally, extremely durable overhead cat-track wire ways eliminatethe more sensitive exposed festooning umbilical cables. Multiplehoist improvements reduce energy consumption and create faster,smoother motions, thereby reducing wear and improving safety forfinishing systems

CONCLUSION

If your company is capital constrained for any reason, the best option toremain competitive is to improve existing equipment incrementally until theeconomy supports a new machine purchase. Clearly, there are many optionsavailable for older finishing systems. Whether load/unload equipment, newcontrols, or hoist automation, Jessup offers productivity improvements pricedto fit any budget.

REFERENCES

1. Jessup Engineering formed in 1971 to manufacture automated hoistsystems for the metal finishing industry. Over the past 39 years, customerdemand drove Jessup to become a turnkey finishing system provider,delivering hoist automation, system components, and peripheralaccessories. With more than 630 systems incorporating 1,250 hoistsand countless conversions installed, the Jessup team has the experienceneeded to integrate an ever-increasing array of mechanical, hydraulic,electric, and electronic upgrade components. We believe in a long-termcustomer focus and support, exacting quality, and on time start-up.In-house mechanical, electrical, controls, parts and service support originatesfrom our Rochester Hills, Mich., location. To learn more aboutJessup Engineering products and services, go to www.jessupengineering.com or call to schedule a visit.

ABOUT THE AUTHOR

Timothy J. Kurcz, director of sales for Jessup Engineering, is also responsible for market andproduct development. A member of the surface engineering community for more than 33years, his experience includes process automation for adhesives, sealants, coatings, electrolyticand electroless plating, fluorescent penetrant inspection, cleaning, passivation, dip-spin,electrocoat, and autophoretic paint coatings. Kurcz can be reached at (248) 853-5600 or via

e-mail at این آدرس ایمیل توسط spambots حفاظت می شود. برای دیدن شما نیاز به جاوا اسکریپت دارید